Ka tsoelo-pele e potlakileng ealithium betriindasteri, maemo a ts'ebeliso ea libeteri tsa lithium a ntse a tsoela pele ho hola le ho fetoha sesebelisoa sa bohlokoa sa matla bophelong ba batho le mosebetsing.Ha ho tluoa tabeng ea tlhahiso ea baetsi ba lithium betri ea customized, mokhoa oa tlhahiso ea betri ea lithium haholo-holo o kenyelletsa metsoako, ho roala, ho roala, ho lokisa, ho lokisa, ho koala, ho roala, ho baka, ente ea metsi, welding, joalo-joalo Tse latelang li kenyelletsa lintlha tsa bohlokoa tsa ts'ebetso ea tlhahiso ea betri ea lithium.Lisebelisoa tse ntle tsa electrode Electrode e ntle ea libeteri tsa lithium e entsoe ka lisebelisoa tse sebetsang, li-conductive agents, li-adhesive, joalo-joalo.Ka kakaretso, sekontiri se hloka ho behoa ka ≈120℃ ka lihora tse 8, 'me PVDF e khomarelang e lokela ho behoa ka ≈80℃ lihora tse 8.Ebang lisebelisoa tse sebetsang (LFP, NCM, joalo-joalo) li hloka ho baka le ho omisa ho itšetlehile ka boemo ba lihlahisoa tse tala.Hona joale, workshop e akaretsang ea betri ea lithium e hloka mocheso ≤40 ℃ le mongobo ≤25% RH.Kamora ho omisa, sekhomaretsi sa PVDF (PVDF solvent, NMP solution) se hloka ho lokisoa esale pele.Boleng ba sekhomaretsi sa PVDF bo bohlokoa ho ho hanyetsa ka hare le ts'ebetso ea motlakase ea betri.Lintho tse amang tšebeliso ea sekhomaretsi li kenyelletsa mocheso le lebelo le sisinyehang.Ha mocheso o phahame, ho mosehla ha sekhomaretsi ho tla ama ho khomarela.Haeba lebelo la ho kopanya le potlakile haholo, sekhomaretsi se ka senyeha habonolo.Lebelo le khethehileng la ho potoloha le itšetlehile ka boholo ba disk ea ho hasana.Ka kakaretso, lebelo la mela ea disk ea ho qhalakanngoa ke 10-15m / s (ho itšetlehile ka thepa).Ka nako ena, tanka ea ho kopanya e hlokeha ho bulela metsi a potolohang, 'me mocheso o lokela ho ba ≤30 ° C.

Kenya slurry ea cathode ka lihlopha.Nakong ena, o hloka ho ela hloko taelo ea ho eketsa lisebelisoa.Qala ka ho eketsa lisebelisoa tse sebetsang le moemeli oa conductive, hlohlelletsa butle-butle, ebe u eketsa sekhomaretsi.Nako ea ho fepa le karo-karolelano ea phepo le eona e tlameha ho kenngoa ts'ebetsong ka thata ho latela ts'ebetso ea tlhahiso ea betri ea lithium.Taba ea bobeli, lebelo la ho potoloha le lebelo la ho potoloha ha lisebelisoa li tlameha ho laoloa ka thata.Ka kakaretso, lebelo la mola oa ho hasanya le lokela ho ba kaholimo ho 17m/s.Sena se itšetlehile ka ts'ebetso ea sesebelisoa.Baetsi ba fapaneng ba fapana haholo.Hape laola vacuum le mocheso oa motsoako.Nakong ena, boholo ba likaroloana le viscosity ea slurry li hloka ho fumanoa khafetsa.Boholo ba likaroloana le viscosity li amana haufi-ufi le litaba tse tiileng, thepa ea thepa, tatellano ea ho fepa le ts'ebetso ea tlhahiso ea betri ea lithium.Ka nako ena, mokhoa o tloaelehileng o hloka mocheso ≤30 ℃, mongobo ≤25% RH, le tekanyo ea vacuum ≤-0.085mpa.Fetisetsa slurry ho tanka ea ho fetisetsa kapa lebenkele la pente.Ka mor'a hore slurry e fetisetsoe ka ntle, e hloka ho hlahlojoa.Morero ke ho sefa likaroloana tse kholo, ho potlakisa le ho tlosa ferromagnetic le lintho tse ling.Likaroloana tse kholo li tla ama ho roala 'me li ka baka ho itšehla thajana ho feteletseng kapa kotsi ea potoloho e khuts'oane;lintho tse ngata haholo tsa ferromagnetic ka har'a slurry li ka baka ho itšehla ho feteletseng ha betri le liphoso tse ling.Litlhoko tsa ts'ebetso ea mokhoa ona oa tlhahiso ea betri ea lithium ke: mocheso ≤ 40 ° C, mongobo ≤ 25% RH, boholo ba marang-rang a skrine ≤ 100 mesh, le boholo ba likaroloana ≤ 15um.

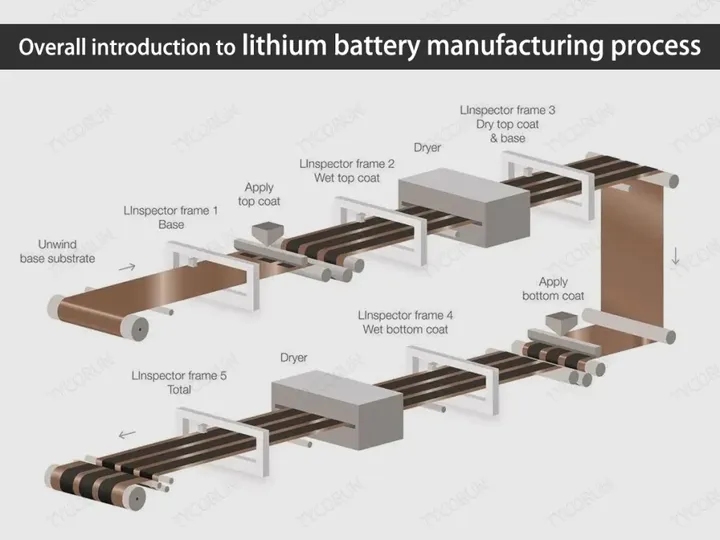

Electrode e mpemetsoako Electrode negative ea lithium battery e entsoe ka thepa e sebetsang, conductive agent, binder le dispersant.Ntlha ea pele, netefatsa lisebelisoa tse tala.Mokhoa o tloaelehileng oa anode ke mokhoa oa ho kopanya metsi (mokelikeli ke metsi a deionized), kahoo ha ho na litlhoko tse khethehileng tsa ho omisa bakeng sa lihlahisoa tse tala.Ts'ebetso ea tlhahiso ea betri ea lithium e hloka hore conductivity ea metsi a deionized e be ≤1us / cm.Litlhoko tsa workshop: mocheso ≤40℃, mongobo ≤25%RH.Lokisetsa sekhomaretsi.Kamora hore lisebelisoa tse tala li khethoe, sekhomaretsi (se entsoeng ka CMC le metsi) se tlameha ho lokisoa pele.Ka nako ena, tšela graphite C le moemeli oa conductive ka har'a motsoako oa motsoako o omileng.Ho kgothaletswa hore o se ke oa phunya kapa oa bulela metsi a potolohang, hobane likaroloana li ntšoa, li phunya le ho futhumala nakong ea ho kopanya ho omileng.Lebelo la ho potoloha ke lebelo le tlaase 15 ~ 20rpm, potoloho ea ho senya le ho sila ke linako tsa 2-3, 'me nako ea nako ke ≈15min.Tšela sekhomaretsi ka har'a motsoako 'me u qale ho hloekisa (≤-0.09mpa).Hlakola rabara ka lebelo le tlase la 15 ~ 20rpm ka makhetlo a 2, ebe u fetola lebelo (lebelo le tlaase 35rpm, lebelo le phahameng la 1200 ~ 1500rpm), 'me u mathe hoo e ka bang 15min ~ 60min ho ea ka mokhoa o metsi oa moetsi ka mong.Qetellong, tšela SBR ka blender.Ho khothaletsoa ka lebelo le tlase kaha SBR ke polymer e telele ea ketane.Haeba lebelo la ho potoloha le potlakile haholo ka nako e telele, ketane ea molek'hule e tla robeha habonolo ebe e lahleheloa ke ts'ebetso.E kgothaletswa ho hlohlelletsa ka lebelo le tlaase la 35-40rpm le lebelo le phahameng la 1200-1800rpm bakeng sa metsotso e 10-20.Teko ea viscosity (2000 ~ 4000 mPa.s), boholo ba likaroloana (35um≤), litaba tse tiileng (40-70%), tekanyo ea vacuum le mesh ea skrine (≤100 mesh).Litekanyetso tse khethehileng tsa ts'ebetso li tla fapana ho itšetlehile ka thepa ea 'mele ea thepa le mokhoa oa ho kopanya.Seboka se hloka mocheso ≤30 ℃ le mongobo ≤25% RH.Coating cathode coating Mokhoa oa tlhahiso ea betri ea lithium e bolela ho ntša kapa ho fafatsa slurry ea cathode holim'a AB holim'a moqokelli oa hona joale oa aluminium, ka sekhahla se le seng sa ≈20 ~ 40 mg / cm2 (ternary lithium betri mofuta).Thempereichara ea sebōpi ka kakaretso e ka holimo ho li-knots tse 4 ho isa ho tse 8, 'me mocheso oa ho baka oa karolo e' ngoe le e 'ngoe o lokisoa pakeng tsa 95 ° C le 120 ° C ho ea ka litlhoko tsa sebele ho qoba mapetsong a pota-potileng le ho rotha ha solvent nakong ea ho baka.Karo-karolelano ea lebelo la rolara ea phetisetso ke 1.1-1.2, 'me sebaka sa lekhalo se fokotsoa ka 20-30um ho qoba compaction e feteletseng ea boemo ba label ka lebaka la mohatla nakong ea baesekele ea betri, e ka lebisang ho pula ea lithium.Ho roala mongobo ≤2000-3000ppm (ho itšetlehile ka thepa le ts'ebetso).Mocheso o motle oa li-electrode workshop ke ≤30 ℃ 'me mongobo ke ≤25%.Setšoantšo sa moralo ke se latelang: Setšoantšo sa moralo oa tepi ea ho roala

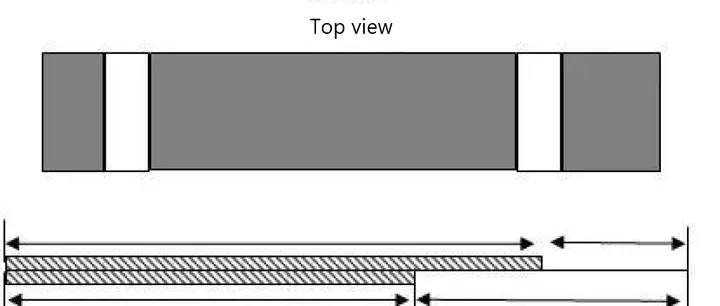

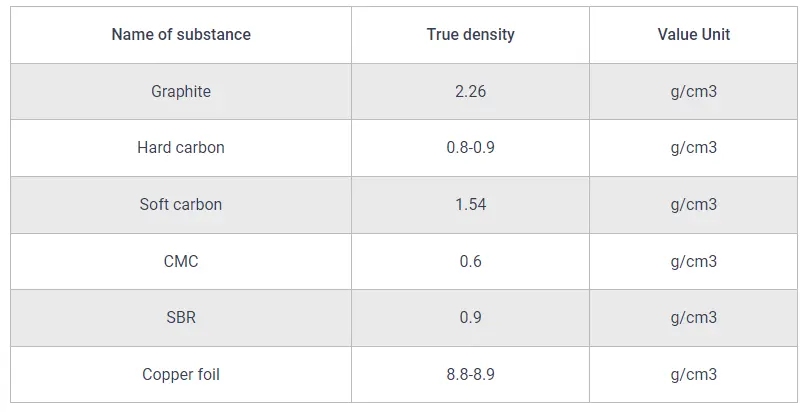

Thetlhahiso ea betri ea lithiummokhoa oaho roala li-electrode tse mpee bua ka extruding kapa fafatsa negative electrode slurry holim'a AB holim 'a koporo hona joale mokelli.Boima ba sefahleho se le seng ≈ 10 ~ 15 mg / cm2.Mocheso oa sebōpi sa ho roala ka kakaretso o na le likarolo tse 4-8 (kapa ho feta), 'me mocheso oa ho baka oa karolo ka' ngoe ke 80 ℃ ~ 105 ℃.E ka fetoloa ho latela litlhoko tsa 'nete ho qoba mapetsong a ho baka le mapetsong a pota-potileng.Lebelo la lebelo la ho fetisa ke 1.2-1.3, lekhalo le tšesaane ka 10-15um, mahloriso a pente ke ≤3000ppm, mocheso o fosahetseng oa electrode sebokeng ke ≤30 ℃, 'me mongobo ke ≤25%.Ka mor'a hore seaparo se setle sa poleiti e ntle e omelle, moropa o hloka ho lumellana ka nako ea ts'ebetso.Rolara e sebelisetsoa ho kopanya letlapa la elektrode (boima ba ho roala ka boholo ba yuniti).Hajoale, ho na le mekhoa e 'meli e metle ea ho hatella li-electrode ts'ebetsong ea tlhahiso ea betri ea lithium: ho hatella ho chesang le ho hatella ho bata.Ha ho bapisoa le ho hatella ho batang, ho tobetsa ho chesang ho na le compaction e phahameng le sekhahla se tlase sa rebound.Leha ho le joalo, mokhoa oa ho hatella o batang o batla o le bonolo ebile o bonolo ho o sebetsa le ho o laola.Lisebelisoa tse ka sehloohong tsa rolara ke ho fihlela litekanyetso tse latelang tsa ts'ebetso, compaction density, rebound rate le elongation.Ka nako e ts'oanang, hoa lokela ho hlokomeloa hore li-brittle chips, li-lumps tse thata, lisebelisoa tse oeleng, li-wavy edges, joalo-joalo ha lia lumelloa holim'a sekhechana sa molamu, 'me likheo ha lia lumelloa ka likheo.Ka nako ena, mocheso oa tikoloho ea workshop: ≤23℃, mongobo: ≤25%.Boima ba 'nete ba lisebelisoa tsa morao-rao tse tloaelehileng:

compaction e sebelisoang hangata:

Sekhahla sa ho khutla: kakaretso e akaretsang 2-3 μm

Elongation: Positive electrode sheet ka kakaretso ke ≈1.002

Ka mor'a hore mochine o motle oa electrode o phethoe, mohato o latelang ke ho arola karoloana eohle ea elektrode ka lihlopha tse nyenyane tsa bophara bo lekanang (ho lumellana le bophahamo ba betri).Ha u slitting, ela hloko li-burrs tsa palo ea palo.Hoa hlokahala ho hlahloba ka botlalo likotoana tsa lipalo bakeng sa li-burrs ka litsela tsa X le Y ka thuso ea lisebelisoa tse peli-dimensional.Longitudinal burr bolelele ba tshebetso Y≤1/2 H botenya ba diaphragm.Mocheso o teng oa workshop e lokela ho ba ≤23 ℃, 'me ntlha ea phoka e be ≤-30℃.Mokhoa oa ho etsa lipampiri tse mpe tsa li-electrode bakeng sa maqephe a lithium betri negative electrode li tšoana le tsa li-electrode tse ntle, empa moralo oa ts'ebetso o fapane.Mocheso o teng oa workshop e lokela ho ba ≤23℃ 'me mongobo o lokela ho ba ≤25%.Boima ba 'nete ba lisebelisoa tse tloaelehileng tse mpe tsa li-electrode:

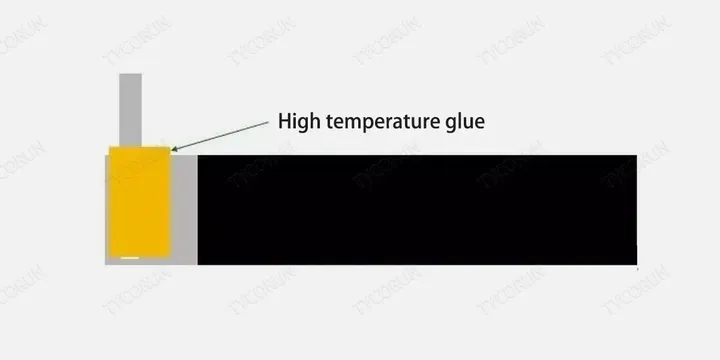

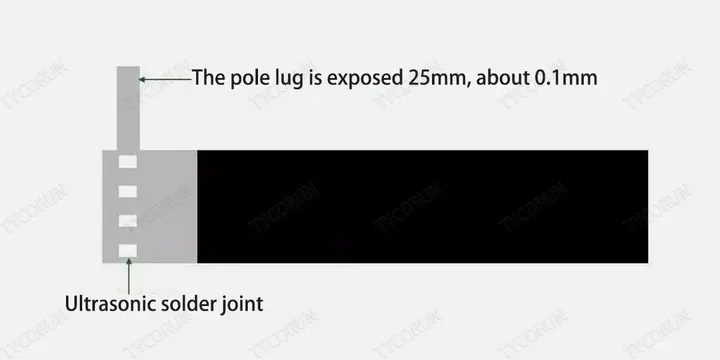

Ka tloaelo ho sebelisoa negative electrode compaction: Rebound rate: General rebound 4-8um Elongation: Positive plate ka kakaretso ≈ 1.002 Ts'ebetso ea tlhahiso ea lithium battery positive electrode stripping e tšoana le e ntle ea electrode stripping process, 'me ka bobeli li hloka ho laola burrs ho X le Y litsela.Mocheso o teng oa workshop e lokela ho ba ≤23 ℃, 'me ntlha ea phoka e be ≤-30℃.Ka mor'a hore poleiti e ntle e se e loketse ho hlobolisoa, poleiti e ntle e lokela ho omisoa (120 ° C), ebe letlapa la aluminium le chesetsoa le ho kenngoa.Nakong ea ts'ebetso ena, bolelele ba li-tab le bophara ba ho bopa bo hloka ho nahanoa.Ho nka moralo oa **650 (joalo ka betri ea 18650) joalo ka mohlala, moralo o nang le li-tab tse pepesitsoeng ke haholo-holo ho nahana ka tšebelisano e ntle ea li-tabo tsa cathode nakong ea li-cap le roll groove welding.Haeba li-tab tsa lipalo li pepesehile nako e telele haholo, potoloho e khutšoanyane e ka 'na ea etsahala habonolo pakeng tsa li-tab tsa pole le khetla ea tšepe nakong ea ho koloha.Haeba mokotla o le khuts'oane haholo, cap e ke ke ea rekisoa.Hona joale, ho na le mefuta e 'meli ea lihlooho tsa ultrasonic welding: linear le point-shaped.Mekhoa ea lapeng hangata e sebelisa lihlooho tsa tjheseletsa tse melang ka lebaka la ho nahana ka matla a overcurrent le welding.Ho phaella moo, sekhomaretsi sa mocheso o phahameng se sebelisoa ho koahela li-tab tsa solder, haholo-holo ho qoba kotsi ea lipotoloho tse khutšoanyane tse bakoang ke li-burrs tsa tšepe le litšila tsa tšepe.Mocheso o teng oa workshop e lokela ho ba ≤23 ℃, phoka e lokela ho ba ≤-30 ℃, 'me mongobo oa cathode o lokela ho ba ≤500-1000ppm.

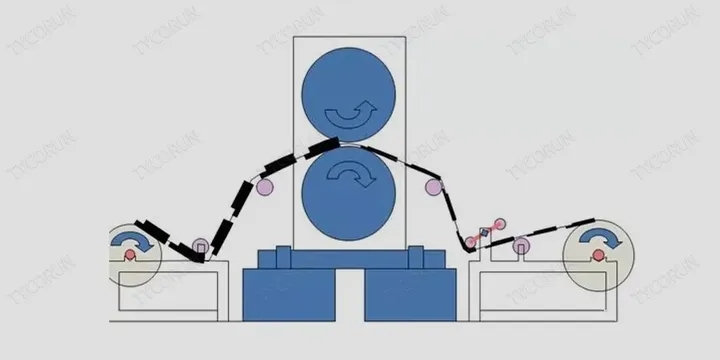

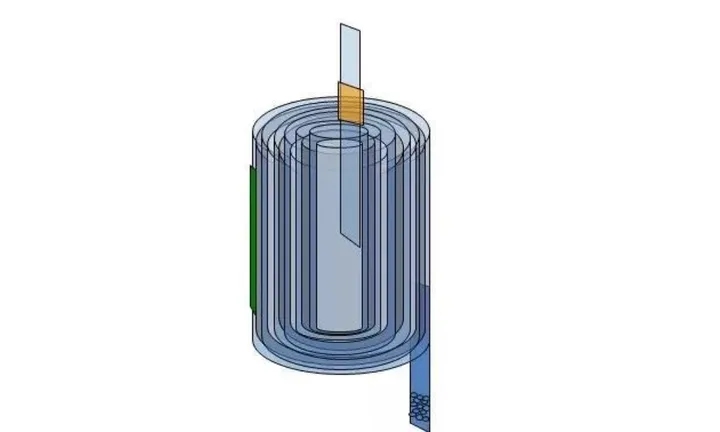

Negative Plate TokisetsoLetlapa le lebe le hloka ho omisoa (105-110 ° C), ebe lipampiri tsa nickel li kenngoa le ho kenngoa.Bolelele ba tabo ea solder le bophara ba sebopeho le tsona li hloka ho nahanoa.Mocheso o teng oa workshop e lokela ho ba ≤23 ℃, ntlha ea phoka e lokela ho ba ≤-30 ℃, 'me mongobo oa electrode e mpe e lokela ho ba ≤500-1000ppm.Maqhubu ke ho phunya separator, lakane e ntle ea eleketrode le lakane e mpe ea eleketrode ho kena mokokotlong oa tšepe ka mochini o tsoelipanang.Molao-motheo ke ho thatela eleketrode e ntle ka eleketrode e mpe, ebe o arola li-electrode tse ntle le tse mpe ka karohano.Kaha electrode e mpe ea tsamaiso ea setso ke electrode ea taolo ea moralo oa betri, moralo oa bokhoni o phahame ho feta oa electrode e ntle, e le hore nakong ea ho tjhaja, Li + tsa electrode tse ntle li ka bolokoa "sekheong" sa electrode e mpe.Tlhokomelo e khethehileng e lokela ho lefshoa ho tsitsipano e tsoelipanang le ho hlophisoa ha likotoana tsa lipalo ha ho tsoelipana.Maqhubu a manyane haholo a tla ama ho hanyetsa ka hare le sekhahla sa ho kenngoa ha matlo.Khatello e feteletseng e ka lebisa kotsing ea potoloho e khuts'oane kapa ho phunya.Ho tsamaisana ho bolela boemo bo lekanyelitsoeng ba eleketrode e mpe, eleketrode e ntle, le searohanya.Bophara ba electrode e mpe ke 59.5 mm, electrode e ntle ke 58 mm, 'me karohano ke 61 mm.Tse tharo li tsamaisana nakong ea ho bapala ho qoba kotsi ea lipotoloho tse khutšoane.Maqhubu a matsoelintsoeke hangata a pakeng tsa 0.08-0.15Mpa bakeng sa palo e ntle, 0.08-0.15Mpa bakeng sa palo e mpe, 0.08-0.15Mpa bakeng sa diaphragm e ka holimo, le 0.08-0.15Mpa bakeng sa diaphragm e tlaase.Liphetoho tse khethehileng li itšetlehile ka thepa le ts'ebetso.Mocheso o teng oa workshop ena ke ≤23℃, phoka ke ≤-30℃, 'me mongobo ke ≤500-1000ppm.

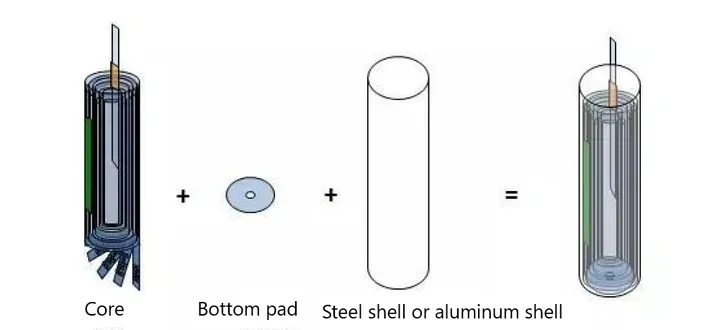

Pele ho kenngoa konokono ea betri ka nyeoeng, ho hlokahala tlhahlobo ea Hi-Pot ea 200 ~ 500V (ho lekola hore na betri e nang le matla a phahameng a motlakase e khuts'oane), 'me vacuum e boetse e hlokahala ho laola lerole pele e kenngoa nyeoe.Lintlha tse tharo tse kholo tsa taolo ea libeteri tsa lithium ke mongobo, li-burrs le lerōle.Ka mor'a hore ts'ebetso e fetileng e phethoe, kenya gasket e ka tlaase ka tlaase ho mokokotlo oa betri, u kobehe letlapa le nang le li-electrode tse nepahetseng e le hore bokaholimo bo shebane le pinhole ea mantlha ea betri, 'me qetellong u e kenye ka har'a khetla ea tšepe kapa khetla ea aluminium.Ho nka mofuta oa 18650 e le mohlala, bophara ba ka ntle ≈ 18mm + bophahamo ≈ 71.5mm.Ha sebaka sa sefapano sa mokokotlo oa leqeba se le senyenyane ho feta sebaka se ka hare-hare sa tšepe ea tšepe, tekanyo ea ho kenngoa ha tšepe e ka bang 97% ho 98.5%.Hobane boleng ba rebound ba palo le tekanyo ea ho kenella ha metsi nakong ea ente ea morao-rao e tlameha ho nahanoa.Ts'ebetso e ts'oanang le sekoahelo sa bokaholimo se kenyelletsa kopano ea sekoaelo se holimo.Mocheso o teng oa workshop e lokela ho ba ≤23 ℃, 'me ntlha ea phoka e lokela ho ba ≤-40℃.

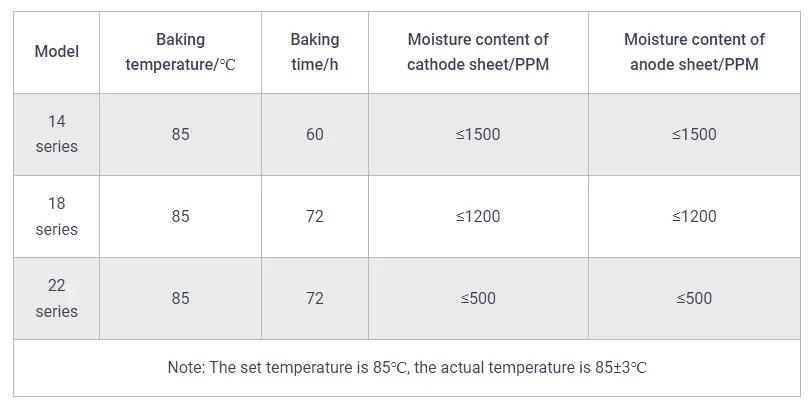

Ho thethehae kenya phini ea solder (hangata e entsoeng ka koporo kapa motsoako) bohareng ba motsoako oa solder.Lithako tse sebelisoang ka tloaelo ke Φ2.5 * 1.6mm, 'me matla a ho tjheseletsa a electrode e mpe e lokela ho ba ≥12N hore e be ea tšoanelehang.Haeba e le tlase haholo, e tla baka habonolo soldering ea sebele le khanyetso e feteletseng ea ka hare.Haeba e phahame haholo, ho bonolo ho cheselletsa lera la nickel holim'a khetla ea tšepe, e leng se hlahisang manonyeletso a solder, e leng se lebisang likotsing tse patehileng tse kang mafome le ho lutla.Kutloisiso e bonolo ea rolling groove ke ho lokisa mokokotlo oa betri ea leqeba ka har'a casing ntle le ho sisinyeha.Ts'ebetsong ea tlhahiso ea betri ena ea lithium, tlhokomelo e khethehileng e lokela ho lefshoa ho bapisa lebelo la transverse extrusion le lebelo la khatello ea longitudinal ho qoba ho khaola casing ka lebelo le phahameng haholo, 'me lesela la nickel la notch le tla oa haeba lebelo la longitudinal le potlakile haholo kapa bophahamo ba notch bo tla ameha mme ho tiisa ho tla ameha.Hoa hlokahala ho hlahloba hore na litekanyetso tsa ts'ebetso bakeng sa botebo ba groove, katoloso le bophahamo ba groove li lumellana le litekanyetso (ka lipalo tse sebetsang le tsa theoretical).Mefuta e tloaelehileng ea hob ke 1.0, 1.2 le 1.5 mm.Kamora hore groove e phetheloe, mochini oohle o hloka ho hloekisoa hape ho qoba litšila tsa tšepe.The vacuum degree e lokela ho ba ≤-0.065Mpa, 'me nako ea vacuum e lokela ho ba 1 ~ 2s.Litlhoko tsa mocheso oa sebaka sena sa workshop ke ≤23 ℃, 'me sebaka sa phoka ke ≤-40℃.Battery core baking Ka mor'a hore maqephe a betri a cylindrical a phutholloe le ho kenngoa, mokhoa o latelang oa tlhahiso ea betri ea lithium o bohlokoa haholo: ho baka.Nakong ea tlhahiso ea lisele tsa betri, palo e itseng ea mongobo e hlahisoa.Haeba mongobo o ke ke oa laoloa ka har'a mefuta e tloaelehileng ka nako, ts'ebetso le polokeho ea betri li tla ameha haholo.Ka kakaretso, ho sebelisoa onto ea "automatic vacuum" bakeng sa ho baka.Lokisetsa lisele tse lokelang ho apeha ka makhethe, kenya desiccant ka ontong, beha litekanyetso, 'me u phahamise mocheso ho 85 ° C (ho nka libeteri tsa lithium iron phosphate e le mohlala).Lintlha tse latelang ke litekanyetso tsa ho baka bakeng sa litlhaloso tse 'maloa tse fapaneng tsa lisele tsa betri:

Mokelikeli EnteTs'ebetso ea ho etsa betri ea lithium e kenyelletsa tlhahlobo ea mongobo ea lisele tsa betri tse besitsoeng.Ke feela ka mor'a hore u fihlele litekanyetso tse fetileng tsa ho baka u ka tsoela pele mohato o latelang: ho kenya electrolyte.Ka potlako kenya libeteri tse besitsoeng ka har'a lebokose la li-vacuum glove, lekanya 'me u tlalehe boima ba tsona, beha kopi ea ente,' me u kenye boima bo hlophisitsoeng ba electrolyte ka har'a senoelo (hangata ho etsoa tlhahlobo ea betri e qoelitsoeng ka metsi: kenya betri ka har'a komiki. bohareng).Kenya konokono ea betri ka har'a electrolyte, e kolobise nako e itseng, leka matla a mangata a ho monya metsi a betri (hangata e tlatsa metsi ho latela bophahamo ba liteko), e behe ka lebokoseng la vacuum ho vacuum (vacuum degree ≤ - 0.09Mpa), le ho potlakisa ho kenella ha electrolyte ho electrode.Kamora 'lipotoloho tse' maloa, tlosa likotoana tsa betri 'me u li lekanye.Bala hore na molumo oa ente o kopana le boleng ba moralo.Haeba e le nyane, e hloka ho tlatsoa.Haeba ho na le ho hongata haholo, tšela feela ho feteletseng ho fihlela u finyella litlhoko tsa moralo.Sebaka sa lebokose la li-glove se hloka mocheso ≤23 ℃ le ntlha ea phoka ≤-45 ℃.

WeldingNakong ea ts'ebetso ena ea tlhahiso ea betri ea lithium, sekoaelo sa betri se lokela ho behoa ka lebokoseng la liatlana esale pele, 'me sekoaelo sa betri se lokela ho ts'oaroa ka har'a hlobo e tlase ea mochini o chesang haholo ka letsoho le le leng,' me mokokotlo oa betri o lokela ho ts'oaroa ka le leng. letsoho.Hlophisa mokotla o motle oa sele ea betri le sekoaelo sa terminal sa sekwahelo.Ka mor'a ho netefatsa hore "terminal lug" e nepahetseng e tsamaisana le cap terminal lug, hata holim'a mochine oa ultrasonic welding.Ebe u hata switjha ea leoto ea mochini oa tjheseletsa.Ka mor'a moo, yuniti ea betri e lokela ho hlahlobjoa ka botlalo ho lekola phello ea welding ea li-tab tsa solder.

Ela hloko hore na li-tab tsa solder li tsamaellana.

Hula ka bonolo tabeng ea solder ho bona hore na e hlephile.

Libetri tseo sekoaelo sa tsona sa betri se sa ts'oaroang ka thata li hloka ho chesetsoa bocha.

Nako ea poso: May-27-2024